Pharmaceutical manufacturing processes require highly controlled environmental conditions and very accurate control of the air characteristics. Moisture is a major concern for pharmaceutical companies, not just because of its effect on production efficiency, product quality and shelf life, but also because of the potential for contaminating sterile drug products. Pharmaceutical products are highly hygroscopic, so keeping the humidity levels under control is crucial to their stability. Temperature and humidity also affect the operating conditions of chemical processes, so regular monitoring is necessary to maintain process consistency, better control, ROI and maximize efficiency.

.jpg)

Surround your product with continuous dry air with desiccant dehumidifiers for protecting pharmaceutical raw material and products during production, storage and transportation from moisture menace. With controlled humidity in production processes, it ensures optimum conditions all year round. Bry-Air desiccant dehumidification system ensures optimum moisture control in storage, packaging etc. regardless of the ambient conditions, at a very low dew point.

Bry-Air is a name trusted in the pharmaceutical industry for over 55 years. We offer scalable systems that can be deployed in each area of research and development, pilot testing and full-scale manufacturing. No matter what your product needs are, Bry-Air Airgineers are equipped and knows how to solve your air quality problems. We offer the ability to design an air quality solution that will fit your specific needs. With our skilled team and extensive knowledge, we will make sure you get the best installation you deserve.

Bry-Air Dehumidifiers are designed to provide dry air continuously, regardless of the ambient conditions, at very low dew point.

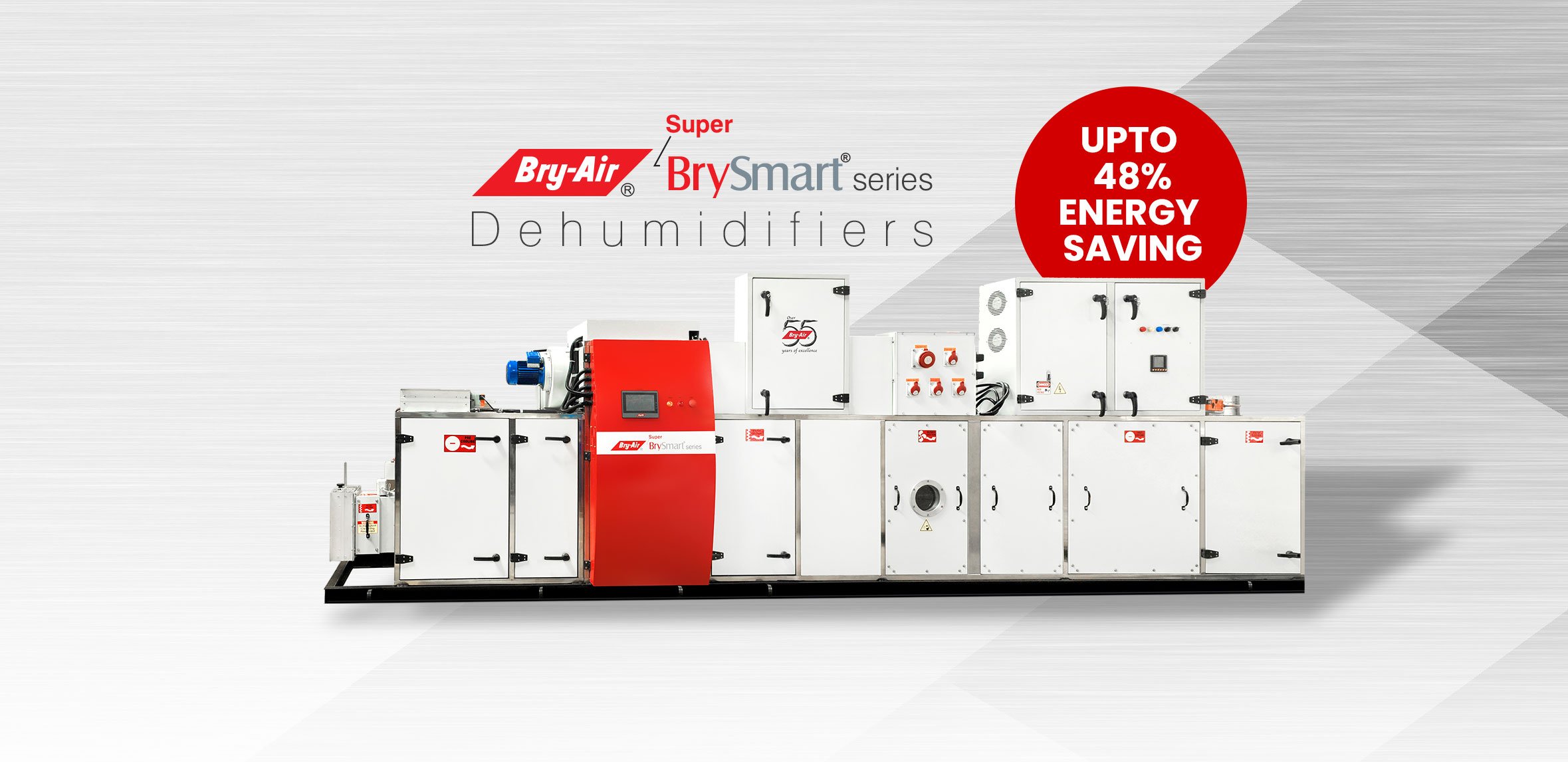

An Industry 4.0 Ready, Smart Energy Efficient Desiccant Dehumidifier

The BBS technology ensures optimization of energy consumption on a continuous basis by modulating various critical components. With a microprocessor control system, Super BrySmart dynamically controls operating variables such as process airflow, rotor speed, reactivation temperature and airflow to optimize performance.

Key Features: